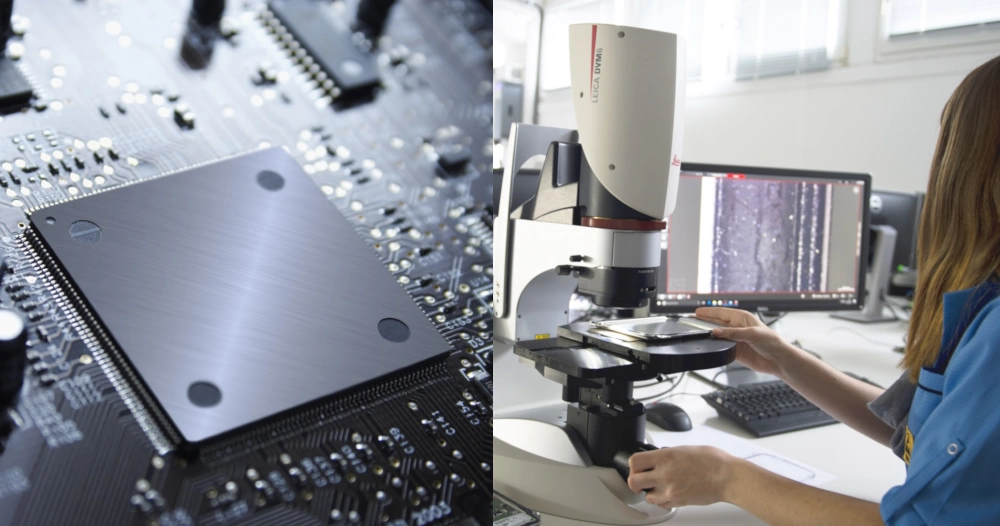

Visual inspection of electronic products

Visual inspection

in accordance with IPC-A610 and IPC-A600

We visually analyze electronic components, assemblies and printed circuit boards - after product testing or in the event of damage. Our visual inspections are carried out in accordance with IPC-A610 and IPC-A600 and are supplemented by our accredited in-house procedure and individual customer solutions.

Quality assurance

through visual inspection of electronic products

What we deliver:

Non-destructive visual inspection in accordance with IPC-A610

(Acceptability of Electronic Assemblies).

Clear classification: Class 1 (general electronics), Class 2 (higher requirements, industry), Class 3 (high-performance). Comprehensive testing of all components: PCBs, solder connections (through-hole and SMT), passive and active components, mechanical components, cables/wire connections, connectors, optoelectronic components.

Customer benefits:

IPC-A610 inspection enables manufacturers to achieve consistent, high-quality assemblies; the customer determines the class to be applied. We combine modern technologies with a trained eye to ensure the highest quality standards.

Class overview:

- Class 1:

General electronic products (consumer goods). Focus on functionality;

lower requirements. - Class 2:

Electronics with higher requirements

(industry, uninterrupted continuous operation; longer service life). - Class 3:

High-performance electronics (e.g. automotive, aerospace, medical, military);

highest requirements and strict tolerances.

Applicable components according to IPC-A610:

- Printed circuit boards (PCBs):

The quality of the printed circuit board, including the solder resist, conductor tracks and vias, is of central importance. - Solder joints:

Criteria for the acceptance of solder joints, including both through-hole and surface mount (SMT). - Passive components:

Typical components are resistors, capacitors and inductors,

where the correct positioning, solder joint quality and mechanical damage are checked. - Active components:

Active components include ICs (integrated circuits), transistors and diodes,

which are also checked for correct placement and soldering quality. - Mechanical components:

Screws, brackets and housings, which are important for the mechanical integrity of the assembly. - Cables and wire connections:

Guidelines for the quality and reliability of cable and wire connections and their fastenings. - Connectors:

These components must be fitted correctly and securely to ensure a reliable electrical connection. - Optoelectronic components:

LEDs, LCDs and other light-emitting or light-receiving components,

where the assembly and soldering quality is crucial.

Your advantage:

- Consistent quality and reliability of your assemblies

- Flexible adaptation to your requirements and standards

- State-of-the-art technologies and trained specialists