Laboratory for the characterization of surfaces and coatings

The planning and implementation of tests, inspections and analyses during development or production is essential for ensuring process and product quality and thus for the satisfaction of your customers. At encontec, we are perfectly positioned to provide you with expert support throughout the entire product cycle.

Services at a glance:

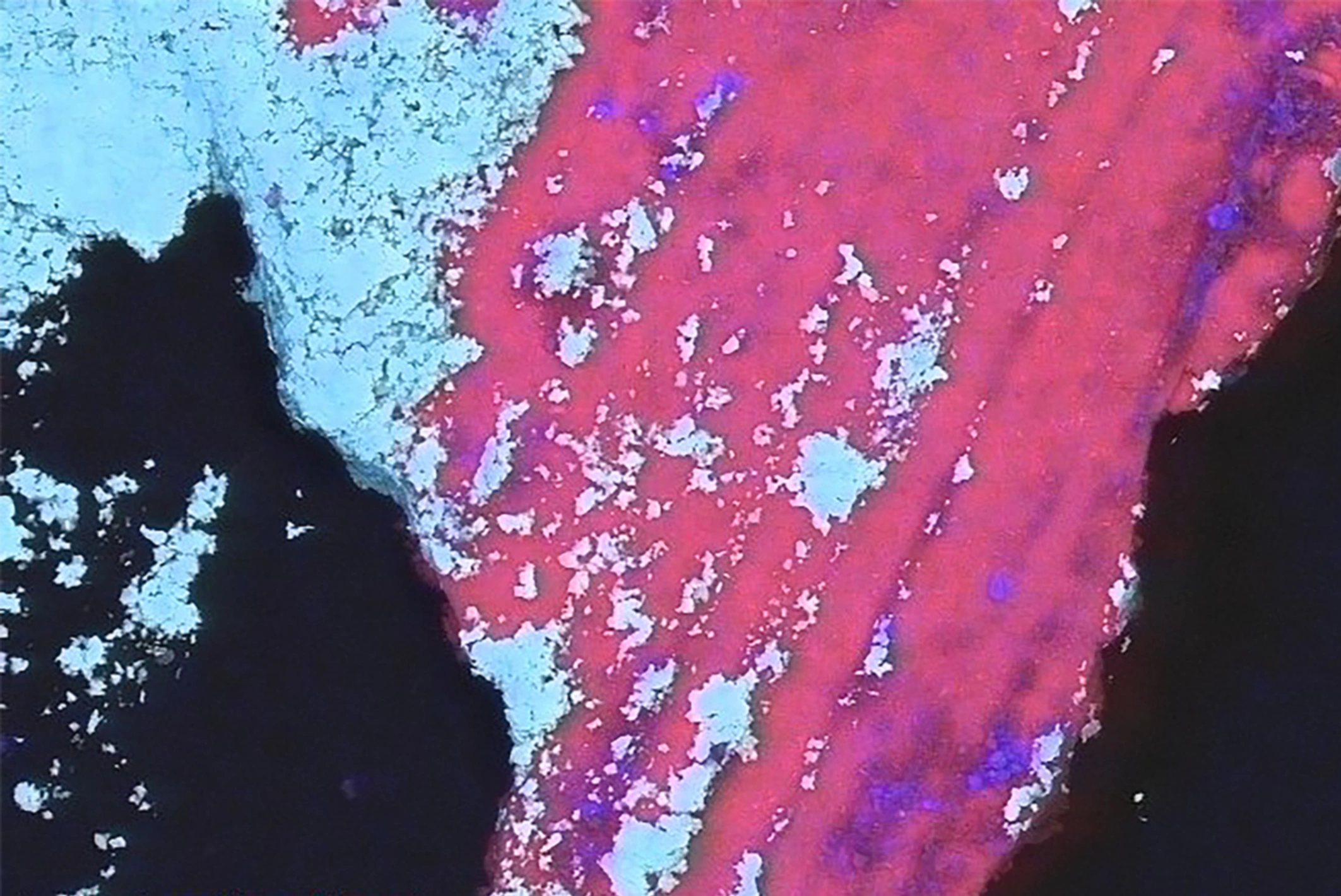

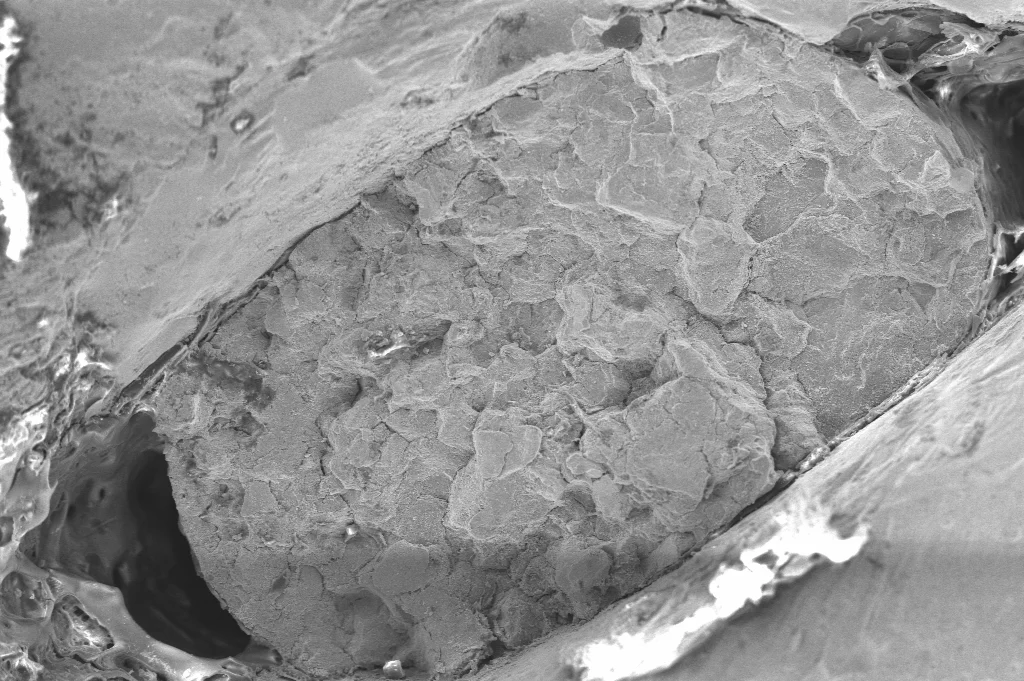

Coating analysis is used to investigate the properties, composition and structure of coatings.

- This enables us to ensure that a coating has the desired properties.

- By measuring the coating thickness, we can ensure that the coating meets the specifications.

- We can check the degree of adhesion between the coating and the substrate.

- With material characterization, we identify the composition of the material, examine the structure of the material and determine the mechanical properties.

- Process optimization through defect analysis of coating defects to prevent future defects.

Excerpt from our portfolio

Layer hardness measurements (NANOINDENTER)

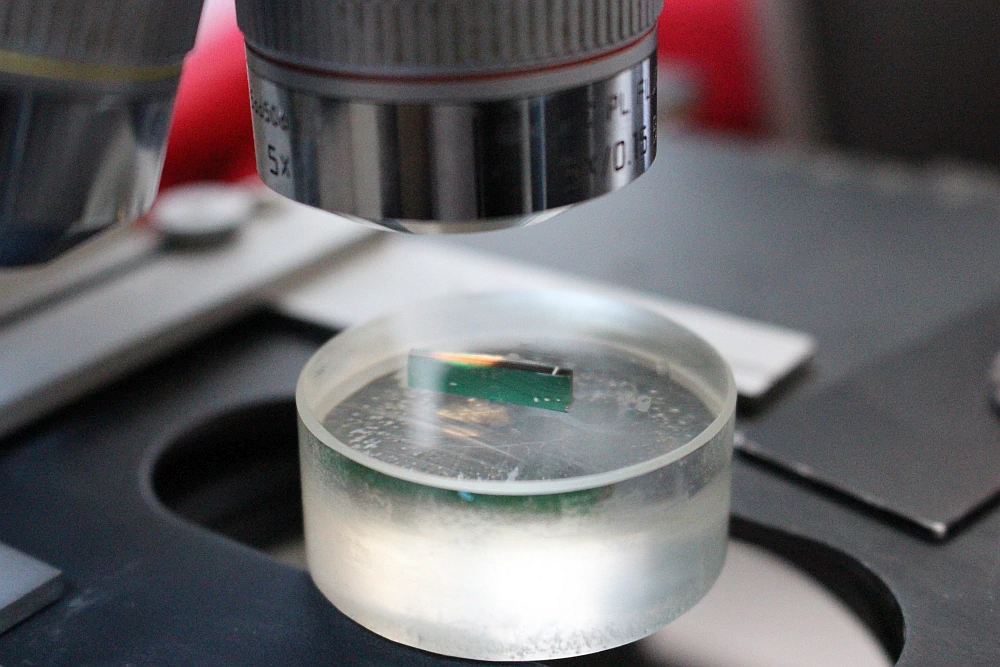

Coating thickness measurement

- Non-destructive, optical

- Destructive via a spherical ground joint according to DIN EN 1071-2

Coating adhesion measurements

- Adhesion test according to VDI standard 3198 (Rockwell)

- Adhesion test with low load (Rockwell) -scratch & - indentation

- Adhesion test with minimum load - Nanoscratch

Microscopy, high-resolution (magnifications from 20 x - 5000 x)

- Laser scanning microscopy

- Investigations of surface roughness/profiles, stages in the coating/coating thickness comparisons

Vibration wear test

- To determine the service life and durability of the coatings