Sampling & cutting technique

Precision that connects - encontec delivers reliable results for your materials testing

Grindings are used in material testing to visualize microstructure, hardness and possible material defects. Both coarse structures and fine details can be visualized with graduated grinding steps. In this way, specific defect patterns can be worked out at certain levels, enabling precise analysis and reliable assessment of the material quality. With state-of-the-art materialographic preparation and high-precision testing methods, our encontec GmbH testing laboratory ensures reproducible results.

Materials at a glance

Steels: Nital (ethanol + nitric acid) to produce ferrite, pearlite or martensite

Copper alloys: Iron-III-Chloride solutions

Aluminum alloys: Fluoride or hydroxide-containing solutions

Sampling & cutting technique:

Safe cutting for meaningful sections

Pre-embedding:

Before cutting, samples or sample areas can be pre-embedded to stabilize them and protect them from vibration damage, chipping or deformation, thereby also preserving sensitive structures and possible defect patterns.

- Cold mounting in various shapes for complex geometries, large samples or complete printed circuit boards, etc.

Separation process:

Selection of the cut-off wheel

- Consideration of material, hardness and specimen geometry

- Selection of the appropriate disk type, grain size and bond

Defining the separation parameters

- Adjustment of cutting speed and feed rate

- Ensure a sufficient and even supply of coolant

Carrying out the separation

- Gentle cutting to avoid cracks, chipping and thermal damage

- Guarantee of a precise and unadulterated sample cross-section

Embedding - stability for precise analysis

Warm embedding

- Process: Embedding under pressure and elevated temperature in thermosetting resin

- Advantages:

- Very stable embedding

- High edge stability

- Particularly suitable for metallic materials

- Restriction:

- Not suitable for temperature-sensitive or pre-damaged samples

Cold embedding

- Process: Embedding at room temperature with liquid synthetic resins

- Advantages:

- Gentle for temperature-sensitive materials and pre-damaged samples

- Suitable for irregularly shaped samples or delicate structures

- Possibility of adding pigments (also fluorescent)

- Applications:

- Highlighting of pores, cracks and inclusions

- Facilitates the microscopic analysis and documentation of defect images

Fine machining for clear structures - Mechanical preparation

- Procedure:

- Grinding with SiC paper in graded grit sizes up to 4000 grit

- Further processing with diamond wheels for harder materials if necessary

- Polishing process is carried out manually, depending on the type of sample with suspensions (e.g. diamond or oxide polishing)

- Advantages:

- Flexible application for different sample types

- Particularly suitable for individual samples or special shapes

Semi-automatic preparation

- Procedure:

- Sample fixation in holders, uniform contact pressure and automated guidance

- Use of SiC paper up to 1200 grit for coarse sanding and fine sanding up to 4000 grit

- Reworking with diamond wheels for particularly hard materials (e.g. steels, hard metals)

- Standardized polishing processes:

- Metallic samples → Diamond suspensions (1-9 µm)

- Ceramic or soft samples → Oxide polish (e.g. aluminum oxide)

- Advantages:

- High reproducibility and consistent surface quality

- Reduction of sample distortion, edge chipping or uneven removal

- Efficient processing of several samples simultaneously

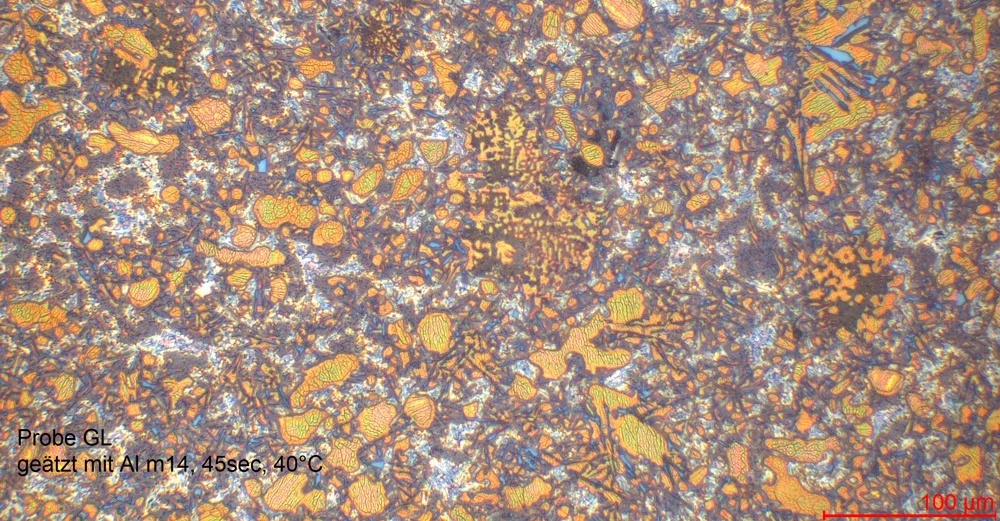

Etching & microstructure analysis - making structures visible

- After preparation (grinding and polishing), specimen surfaces are mirror-smooth and microstructures are not recognizable

- Differences in chemical composition or grain boundaries are made visible through etching

Chemical etching:

- Application or immersion of the sample in a suitable etchant

- Control of exposure time, temperature and concentration to avoid over- or under-etching

- Thorough rinsing and drying of the sample after etching

- Different structural components react differently to the etchant

- Grain boundaries, precipitates or secondary phases stand out in such high contrast

- Steels: Nital (ethanol + nitric acid) to produce ferrite, pearlite or martensite

- Copper alloys: Iron-III-Chloride solutions

- Aluminum alloys: Fluoride or hydroxide-containing solutions

Geometric characteristics & error evaluation -

Standardized analysis for maximum significance

Macroscopic analysis:

- Viewing range: with the naked eye or under low magnification (up to approx. 25x)

- Examination of the rough microstructure and visible defects

- Typical applications:

- Detection of blowholes, cracks, pores or welding defects

- Evaluation of e.g. coarse structures or heat treatment zones

- Often as an initial overview of the sample before microscopic examination

Microscopic analysis:

- Viewing range: under light microscope or electron microscope (magnifications 50x to several 1000x)

- Objective: Investigation of the fine microstructure and individual phases

- Typical applications:

- Analysis of grain sizes, phases (e.g. ferrite, pearlite, martensite)

- Detection of precipitates, inclusions or very fine cracks

- Quantitative evaluations with image analysis

- Use: detailed assessment of material quality and functional reliability