Encontec examines what matters

Weld seam analysis at the highest level - safety starts with precision

In the automotive industry, in the construction and steel industry, in aviation, in shipbuilding or in the oil and gas industry: high-quality welded joints are indispensable. Especially in the case of safety-critical components or under extreme operating conditions, the quality of the weld seam is decisive for function, service life and safety.

encontec is your reliable partner for comprehensive weld seam testing - certified, precise and fast

Our test methods - non-destructive & destructive:

Weld seam analysis is used for quality assurance and defect detection of welded joints. The aim is to check the mechanical strength, microstructure, chemical composition and possible weak points of the weld seam. Non-destructive and destructive testing methods are used.

Non-destructive testing method

Visual testing (VT)

- Description: First, basic test, usually directly after welding.

- Objective: Detection of visible defects such as cracks, pores, binding defects, burn marks or

weld spatter. - Procedure:

- Use of magnifying glasses, endoscopes or cameras possible.

- Control according to standards.

- Fast, cost-effective and can be carried out directly on the component.

- Only surface defects visible, no statement about internal defects.

Typical defects such as pores, blowholes, cracks or dimensional deviations are reliably made visible.

Destructive testing methods

Focus on mechanical and technological properties:

Vickers hardness test

- Mechanical test to determine the hardness in the weld metal, heat-affected zone (HAZ) and base material.

- Check whether the weld seam has become too brittle or too soft due to the influence of welding.

- Detection of hardness peaks (risk of cracking).

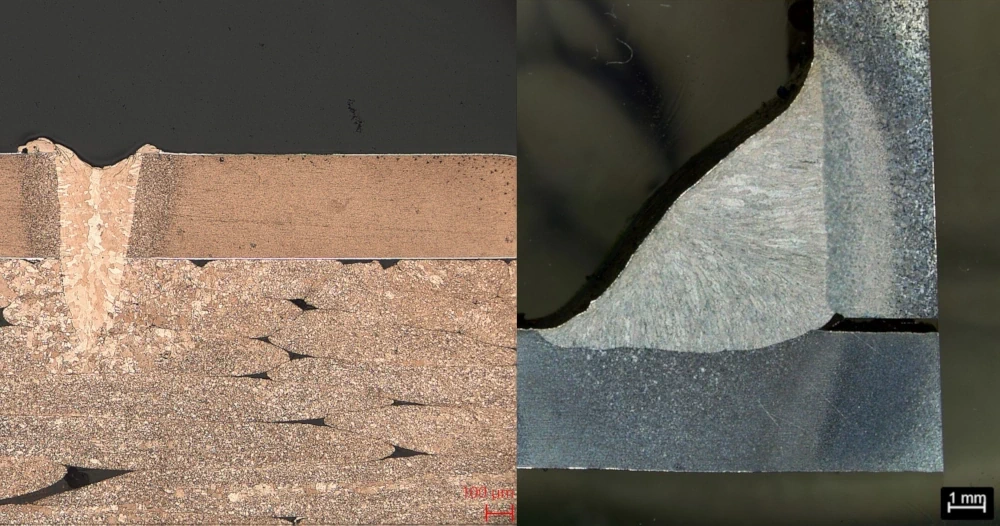

Metallographic investigations

- Examination of the microstructure in the micrograph.

- Taking a sample from the weld seam.

- Preparation (grinding, polishing, etching).

- Analysis under the light microscope.

- Visualization of microstructure types (ferrite, martensite, austenite, etc.).

- Detection of micro-defects, e.g. blowholes, pores, cracks.

- Provides important information about heat conduction, solidification and possible weak points.

- Can be performed with optical microscopy as well as in combination with SEM/EDX.

- Often mentioned together with microscopic micrograph analysis, but includes more:

- Investigation of micro and macro structures.

- Identification of defects such as blowholes, inclusions, cracks or segregations.

- Comparison with target structures.

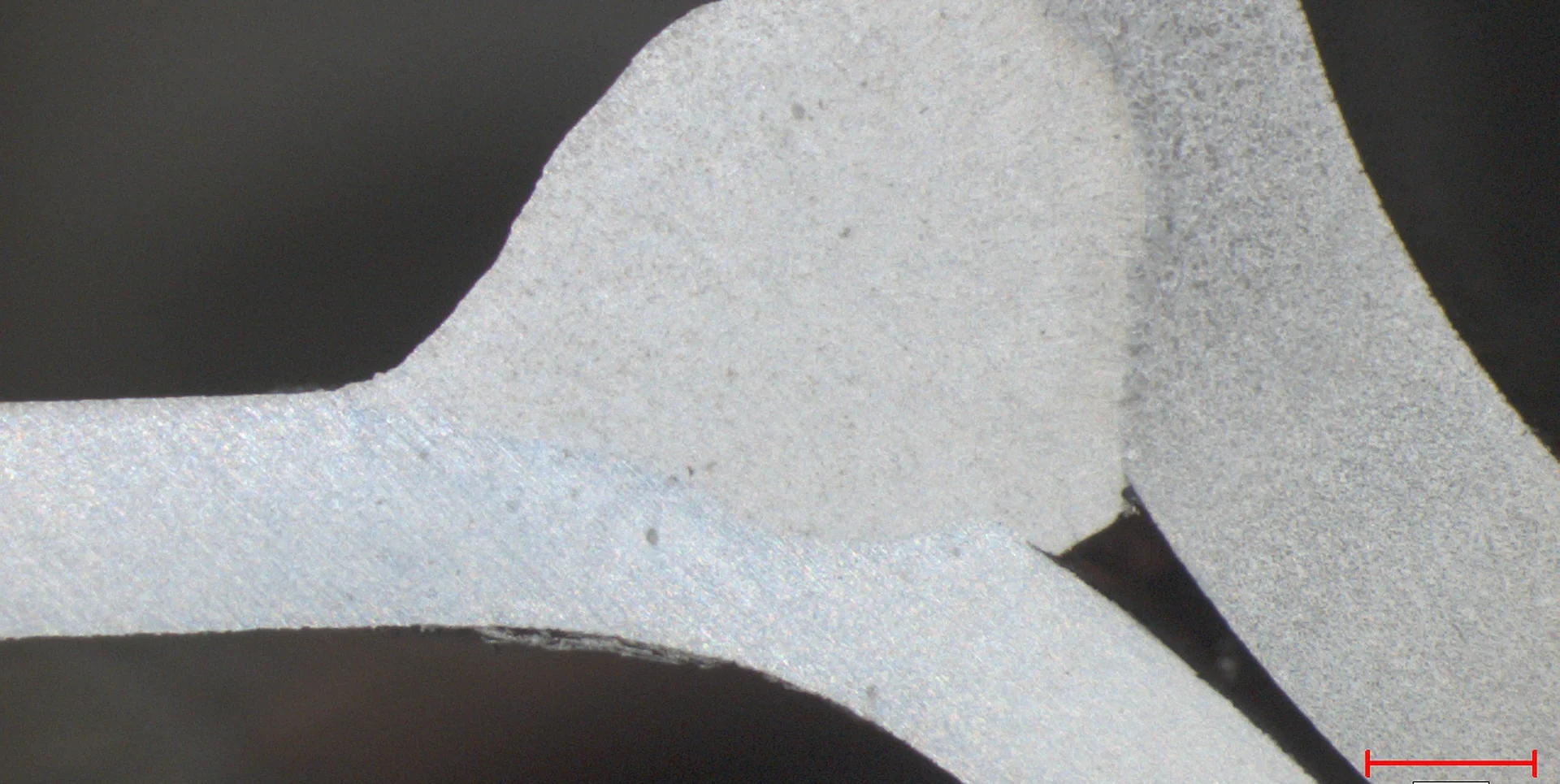

Microscopic analysis on the section with without etching

- Examination under a light and/or digital microscope.

- Representation of the microstructure (ferrite, pearlite, bainite, martensite, austenite, etc.).

- Detection of structural changes due to the heat-affected zone.

- Analysis of the seam geometry and weld penetration.

- Measurement of seam depth and width, A-measurement, undercamber, etc.

Provides valuable information about the welding quality that cannot be seen with the naked eye.

SEM/EDX analyses

(scanning electron microscopy with energy dispersive X-ray spectroscopy)

- REM:

- High-resolution imaging (up to nanometer range).

- Examination of the finest surface structures, pores and cracks.

- EDX:

- Element analysis directly at certain points in the cut.

- Identification of alloy components and foreign inclusions.

Precise failure and damage analysis at micro and nano level, not part of the accredited area.