Absolutely - safely tested

Accredited test laboratory - in Stuttgart

Accredited testing laboratory

- in Stuttgart

No matter what industry you work in - whether in mechanical engineering, the automotive industry or the medical sector - the planning and implementation of tests, inspections and analyses during development is essential for ensuring process and product quality and the satisfaction of your customers. At encontec, we are perfectly positioned to provide you with expert support throughout the entire product cycle.

Ground joint position

Ground joint position

MoreWeld seam analysis

Weld seam analysis

MoreMicrostructure analysis

Microstructure analysis

MoreMaterial analysis

Material analysis

MoreVisual inspection

Visual inspection

MoreDiagnosis of test specimens

Diagnosis of test specimens

MoreREM

REM

MoreEDX analysis

EDX analysis

MoreWhisker analysis

Whisker analysis

MoreDamage analysis

Damage analysis

MoreFracture surface analysis

Fracture surface analysis

MoreSurface topography / LSM

Surface topography / LSM

MoreRoughness measurement

Roughness measurement

MoreHardness test

Hardness test

MoreTensile and pressure testing

Tensile and pressure testing

MoreLeak test / Bubble test

Leak test / Bubble test

More

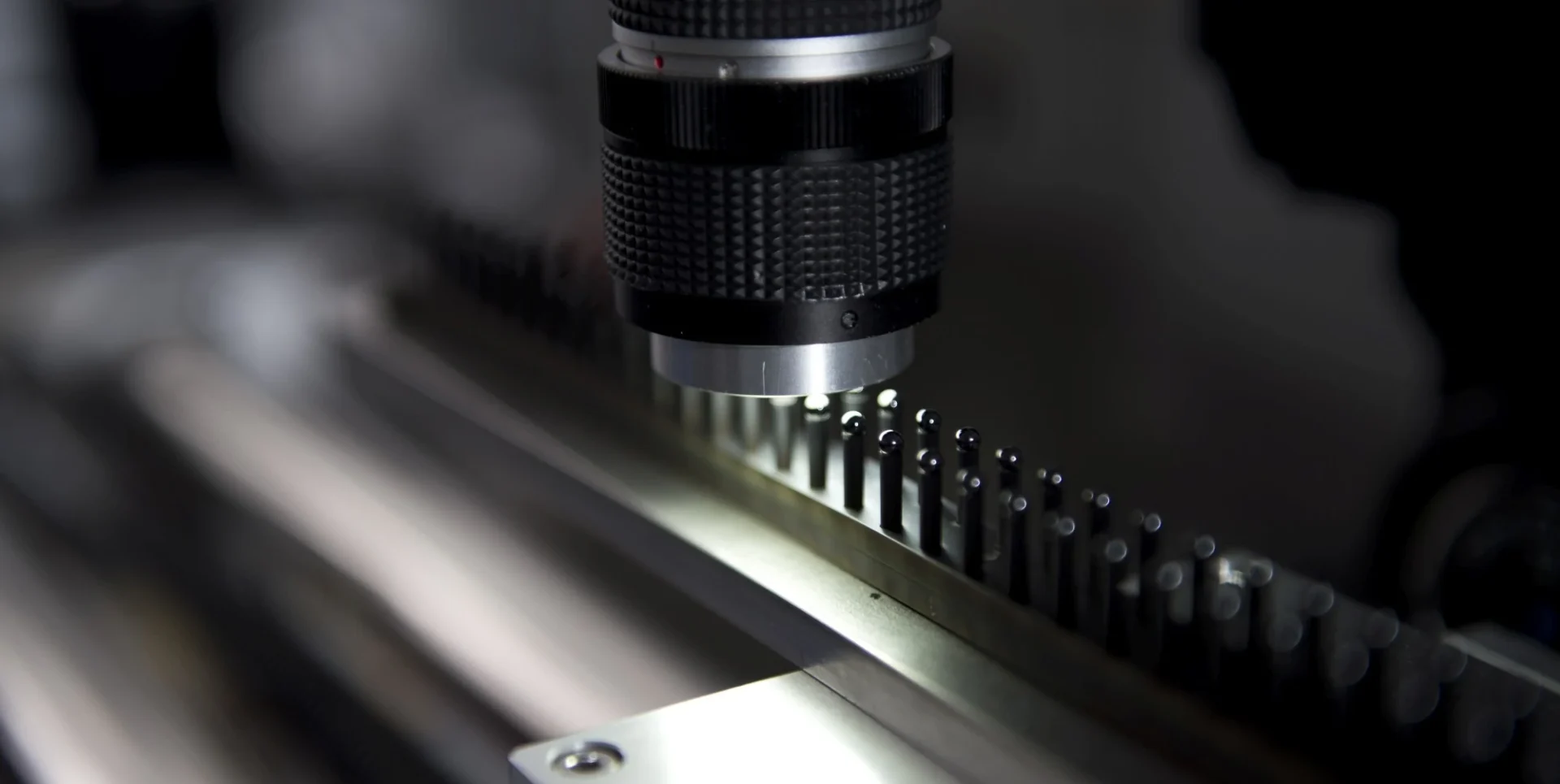

Ground joint position

The creation of sophisticated cuts on electronic components and the precise assessment of the connection to the circuit board are part of our expertise, as is the creation of cuts on any other components. We carry out a thorough analysis of cracks, crack patterns and pores in solder joints to ensure that your electronic assemblies are free of defects. With our accredited in-house procedure for the measurement of cracks in solder joints, we offer you a professional and reliable standard for the quality control of your components.

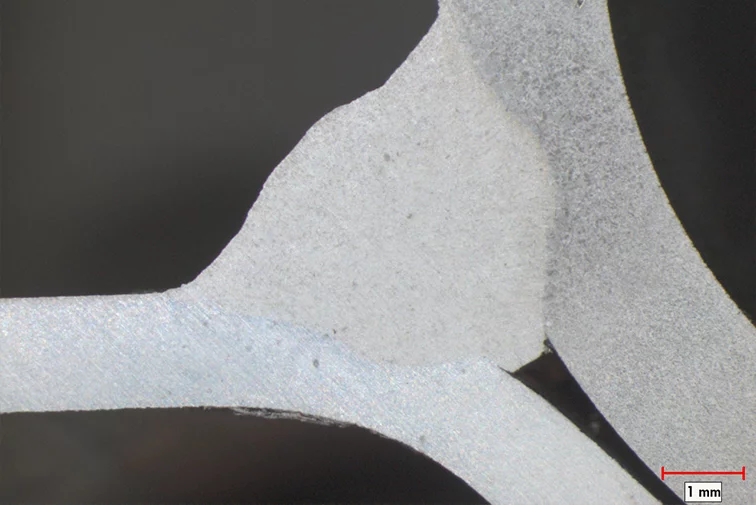

Weld seam analysis

Are you looking for precise and reliable analyses of weld seams? Then you've come to the right place!

Our experts in the laboratory provide you with detailed insights into the quality and integrity of your weld seams. With our weld seam analysis, you can detect potential defects at an early stage, improve the strength and durability of your welds and thus save costs. Whether MIG/MAG, TIG, manual arc welding, laser welding or other welding processes - we offer you customized weld seam analyses for every application.

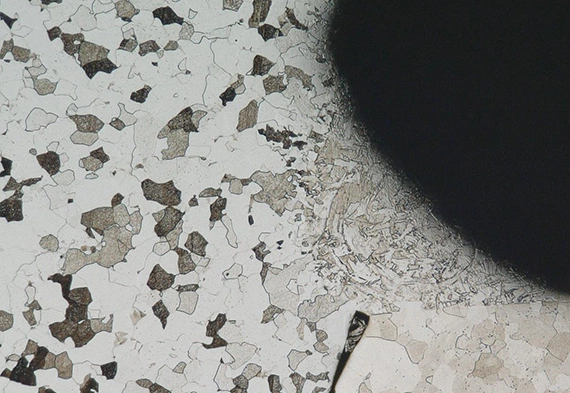

Microstructure analysis

We offer precise analysis of material structures for metals, ceramics, polymers and composites. We provide sound insights into the structure, composition and properties of your samples. Identify quality problems, investigate damage and uncover optimization potential.

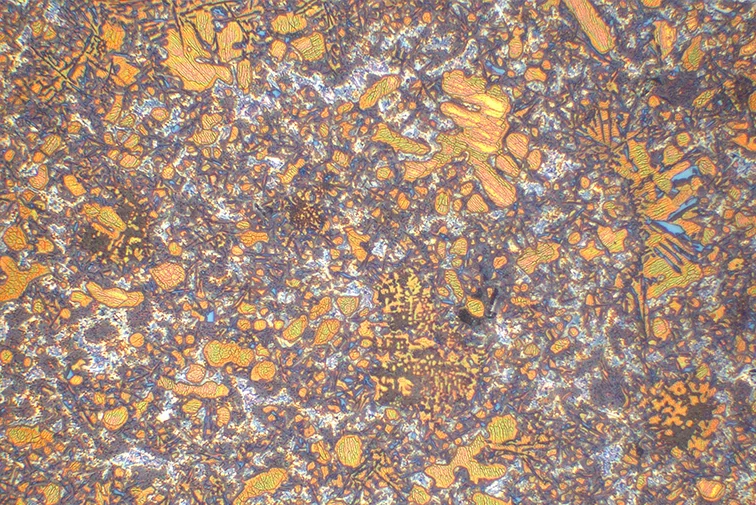

Material analysis

With our material analysis, we offer a precise examination of the composition of your materials. We identify and analyze inclusions, precipitates, signs of corrosion, stains, impurities, grain sizes and grain size distributions. Using various modern methods, we precisely determine the chemical composition of your materials and provide you with detailed insights.

Visual inspection

We specialize in the visual analysis of electronic components, assemblies and printed circuit boards after product testing or in the event of damage. With many years of experience and expertise, we carry out visual inspections in accordance with the IPC-A610 and IPC-A600 standards. We also provide analyses in accordance with our accredited in-house procedure or adapt to your individual requirements. With state-of-the-art technologies and a trained eye, we ensure that your components and assemblies meet the highest quality standards.

Diagnosis of test specimens

Our test item diagnostics ensure precise analysis of your test results. We identify defects or deviations and carefully evaluate their impact on the quality of your products. Based on these findings, we develop customized measures to continuously improve your product quality.

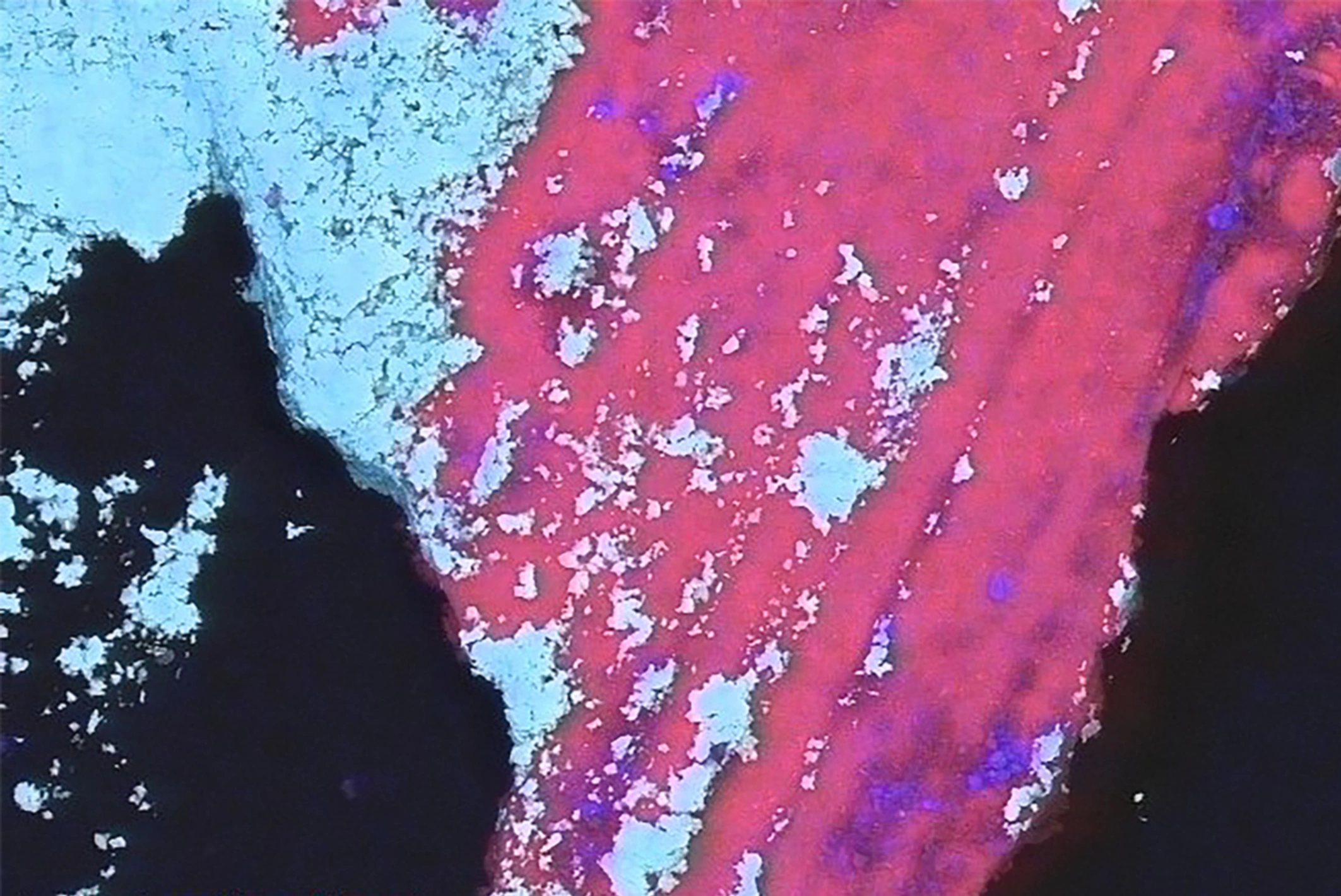

Scanning electron microscopy

With our scanning electron microscopy, you can view the smallest particles, surfaces and materials with unprecedented sharpness and magnification. Use our services to optimize your research results and gain new insights. Thanks to the EDX detector, we can not only visualize surface structures, but also determine the chemical composition of samples.

The CL detector can be used to identify fluorescent plastic layers or cracks. Fluorescent minerals can also be examined.

EDX analysis

Our EDX analysis (energy dispersive X-ray spectroscopy) enables precise analysis of your materials. This method enables us to precisely determine the material composition and carry out a thorough analysis. This gives you detailed insights into the chemical properties of your samples.

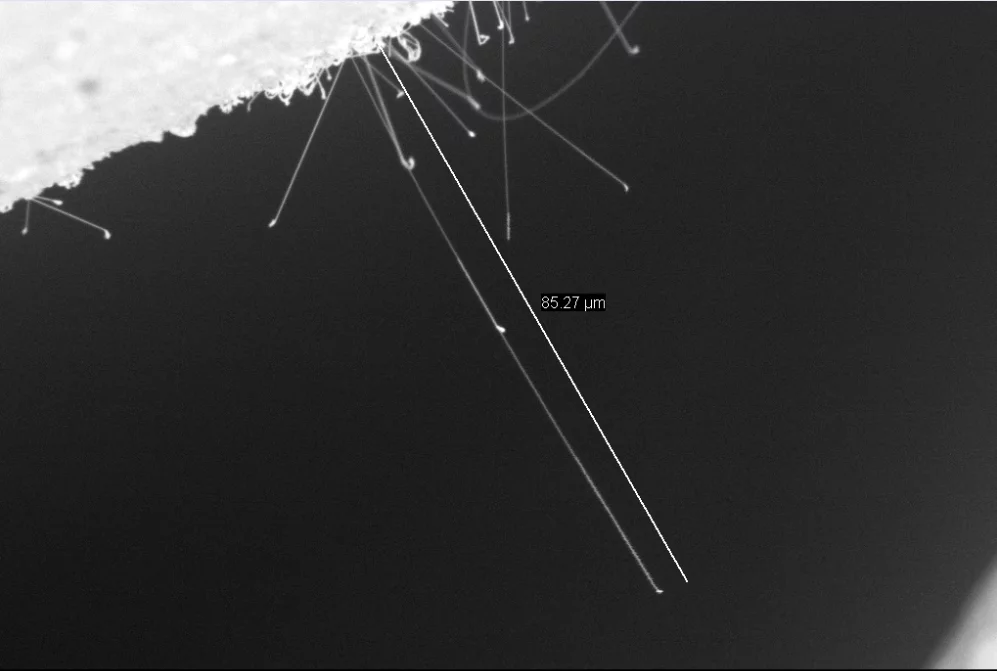

Whisker analysis

Whiskers growing in an electrical circuit or a connection section can cause short circuits that can lead to failures of electrical products.

The analysis and prevention of whisker growth are therefore crucial for the safety and reliability of electrical products. We have in-depth expertise in the analysis of whiskers. Using our state-of-the-art laboratory equipment, we examine your components and determine the presence, length and location of whiskers

Damage analysis

With our damage analysis services, we support you in finding the cause of the defect. Using state-of-the-art technologies such as scanning electron microscopy, hardness tests, visual analyses, EDX analyses, roughness tests and much more, we offer you all the necessary analyses. Regardless of your industry, we are your partner for reliable analyses.

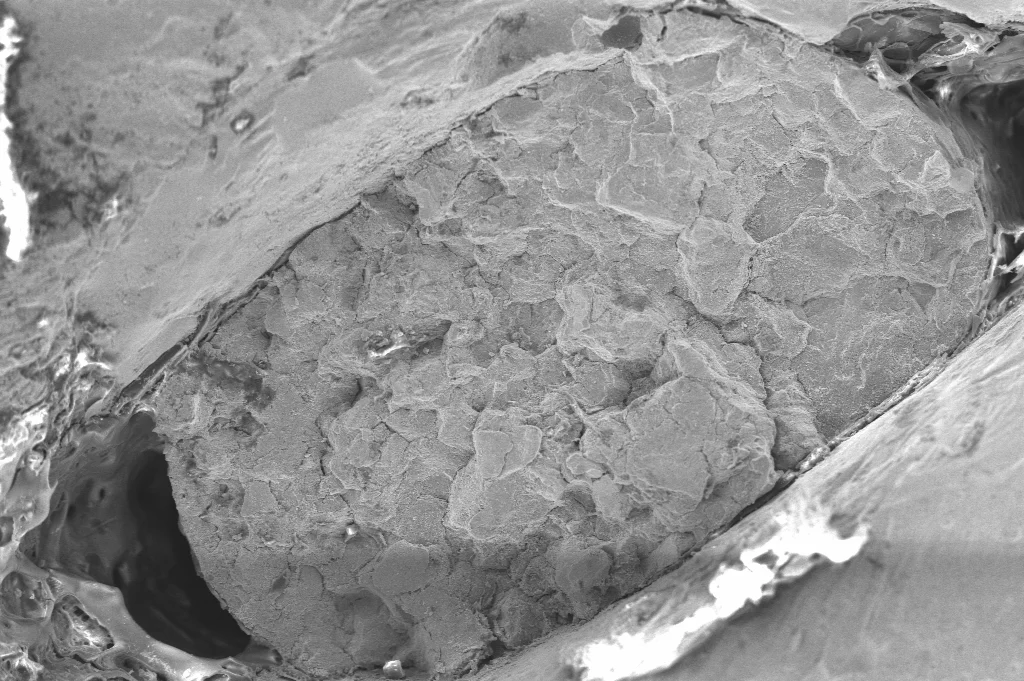

Fracture surface analysis

Our portfolio includes precise examinations of fracture surfaces of various materials to help you identify the causes of damage and develop preventive measures. We analyze fracture surfaces of metals, plastics, ceramics and composites to help you solve quality problems and ensure the safety of your products.

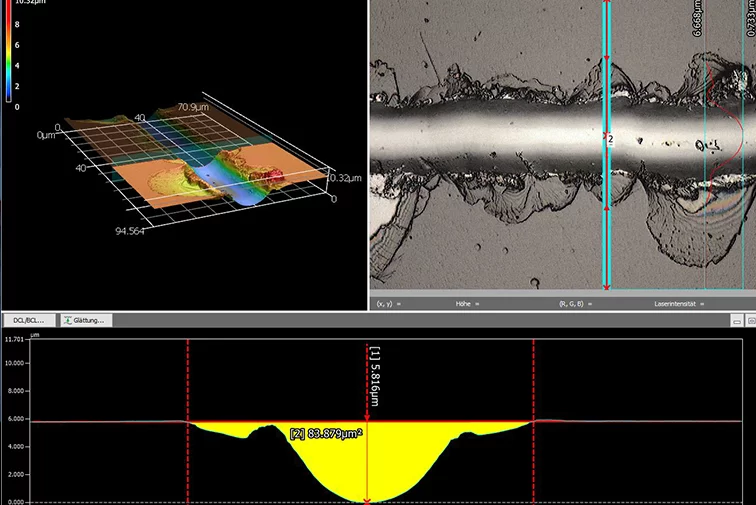

Surface topography / LSM

Our modern laser scanning microscope enables you to visualize and analyse the finest details and structures on surfaces. In addition, it offers the unique possibility of measuring the surface roughness in the radius and thus carrying out a comprehensive characterization of the surface. We can visualize and analyse the captured data for you in impressive 3D representations. The finest details and structures are made visible.

Roughness measurement

Our roughness measurements are carried out using a tactile measuring machine in accordance with DIN EN ISO 21920-2. We offer you a reliable solution for checking the surface quality of your components. It is also possible to test the roughness in the radius with our LSM microscope.

Hardness test

The Vickers hardness test in accordance with DIN EN ISO 6507-1 is a standardized method for measuring the surface hardness of metals, ceramics and other materials (measuring range: between HV 0.05 and HV 10). Our experts carry out this test with the highest accuracy to provide you with detailed information about the mechanical properties of your samples. Place your trust in our expertise!

Tensile and pressure testing

Our tensile and compression tests allow us to reliably determine the mechanical properties of materials such as tensile strength, elongation at break, yield strength and compressive strength. We are particularly specialized in measuring press-out forces on the pins of the male connectors of control units. We manufacture the corresponding devices in-house.

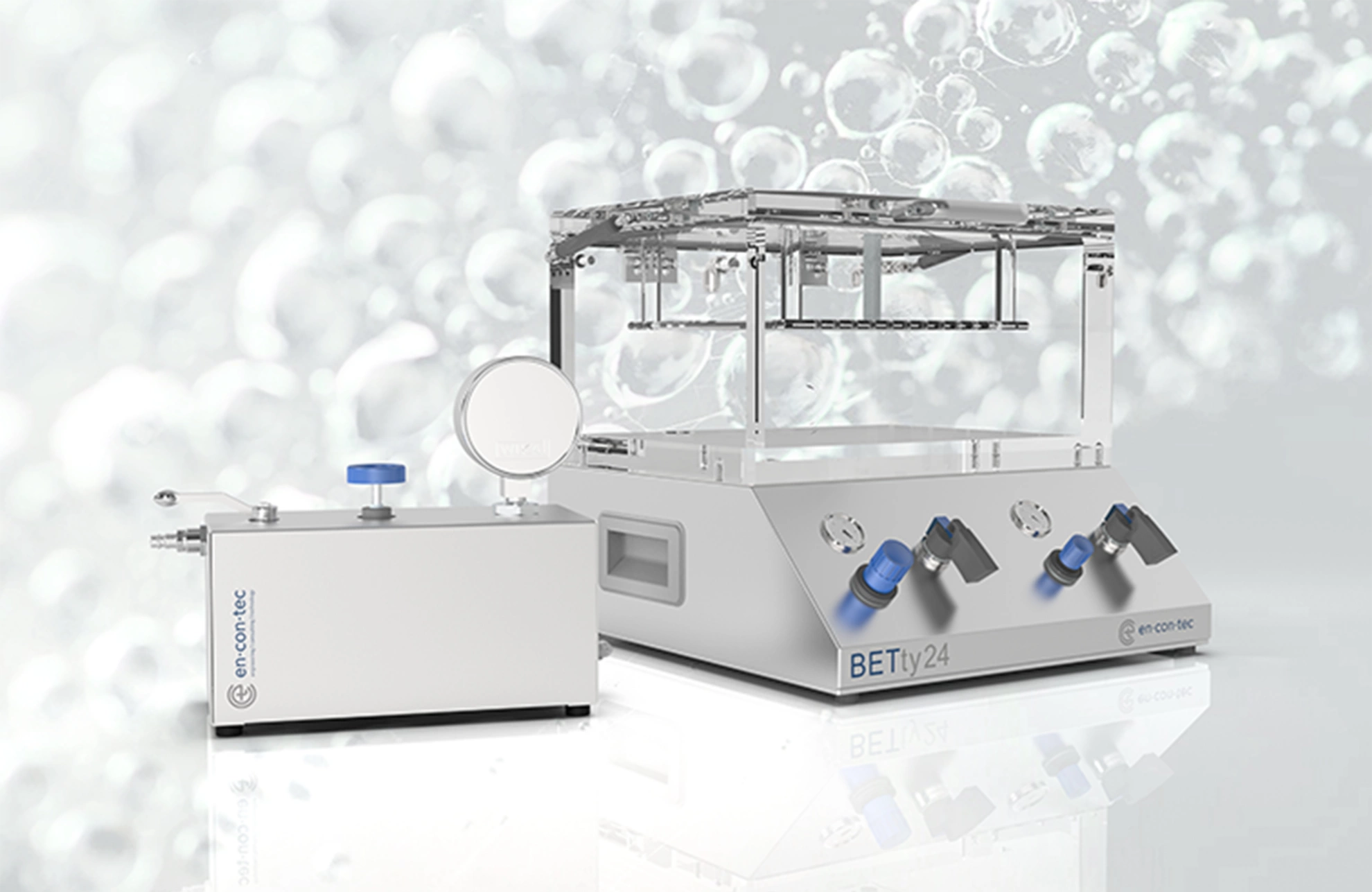

Leak test / bubble test

Our Bubble Emission Test System, BETty, is a water bath leak detection system used to locate leaks in all flexible and rigid packaging types and various components. With its precise technology, BETty provides a reliable method to identify leaks quickly and efficiently, contributing to improved product quality and

safety.

Accredited test laboratory

Our test laboratory is accredited in accordance with DIN EN ISO/IEC 17025:2018. As part of our flexible accreditation, the test procedures can be individually tailored

- Test procedures of our flexible accreditation.

We work with state-of-the-art technical equipment on over 300m2. We provide qualified advice, respond quickly and attach great importance to high quality standards. We offer comprehensive services in the fields of materials testing. Our test results provide a valid basis for your damage analysis.

CONFORMITY OF TEST RESULTS

Our decision rule for conformity statements applies to the handling of your measurement results with regard to measurement uncertainties.

State-of-the-art testing technologies

Our state-of-the-art technical equipment includes a wide range of devices that enable us to provide you with the best possible test results. This includes, for example

- SEM - Scanning electron microscope

- EDX - energy dispersive X-ray analysis

- Reflected light / transmitted light microscopes

- Stereomicroscopes

- Digital microscopes

- LSM - Laser scanning microscope

- Grinding and polishing equipment

- Cut-off machines

- Diamond wire saw

- Heating ovens

- Tensile-pressure testing machine

- Roughness meter

- Hardness testers

- ZNH-S nano hardness tester

- Hot/cold embedding and rapid embedding

Get all the information you need about our range of services.